New & Trending Posts

50+ Beautiful Wooden Side Tables & End Tables You Must See!

If you’re looking for inspiration to buy or create your wooden side table, you’ve come to the right place. As a woodworker, my first project was to create a pine

How My Humble Woodworking Workshop Evolved Over 8 Incredible Years

As a woodworker, your woodworking workshop or woodshop is your universe. It is your office, very often your second home, and always your place to get lost in yourself. My

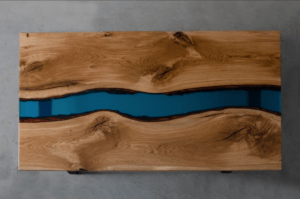

50+ Amazing Epoxy River Table Ideas for Your Inspiration

I’ve always been attracted to building my own river table or epoxy table for years, yet I never actually got to make one. I understand the concept of a river

A Handmade Wooden Pet Urn for A Special Bird

A while back I received a custom order for a handmade wooden pet urn, and in this post, I want to highlight my creation. This was my first time making

Luban Block Plane Review – Low-Angle Block Plane

I bought a Luban plane for $69 recently, and I thought I would share what I think about it here. While I try to describe as much as possible in

Incredible Hearing Protection Headphones for Woodworking – Dewalt DPG17

You need good hearing protection headphones if you’re a woodworking worker with noisy tools like a planer or table saw. There are many in the market, but which are the

Build an Effective Chisel Sharpening Jig DIY Under 15 Minutes

I built a new chisel sharpening jig to make it easier to sharpen chisels, hand plane blades and marking knives. I’m making a quick and dirty build using: The measurements

Veritas Small Shoulder Plane Review – PMV11 Blade

I decided to get a Veritas small shoulder plane not too long after I received my Veritas medium router plane. Since I make small woodworking craft like watch boxes and

In-Depth Guides & Resources

Best Wood Lathe Tools for 2024 – Turning Tools, Grinders & Jigs

Get the most out of your lathe with this list of the best work holding, shaping, turning and refining tools. From chucks to carbide, I’ve filtered only the most important tools every woodturner needs.

Best Pen Turning Tools, Kits & Supplies

Start turning pens with this complete guide to pen kits, pen turning tools, pen blanks, and other useful guides to get started in no time.

Stabilized Wood 101 – Everything About Stabilizing Wood

Ever since I discovered stabilized wood, I’ve been attracted to the idea of using them in my projects.

Best Circular Saw for 2024 – Compact & Cordless Circular Saws

Circular saws are one of the most important tools for on-site woodworking and cutting up large sheets. Here are the most affordable circular saws you can buy.

Best Woodworking Bench for 2024 – Budget and Premium Workbenches

What are the best woodworking benches you can buy today? Find out now, from our carefully-selected list of workbenches that scored the highest on Amazon!

Best Wood Lathes for 2024 – Mini & Midi Wood Lathes – JET, Rikon, WEN & More

A wood lathe is a great addition to any workshop, even if you’re a hobby woodworker. Here’s my guide to the best wood turning lathe machines.

The Ultimate DIY Workbench Building Guide

Whether you’re a hand-tool or power-tool woodworker, building your first DIY workbench is absolutely important. This guide is your perfect place to get started.

Best Benchtop Planers & Thicknessers

Take your woodworking to the next level with a benchtop planer or thicknesser. Get your boards dimensions spot on for better joints and more professional work.

Latest Videos

Random Posts

Black & Decker Workmate 225 Review

Before you read this review of the Black & Decker Workmate 225 portable workbench, I have to warn you that I’m not a professional reviewer.

50+ Beautiful Wooden Side Tables & End Tables You Must See!

If you’re looking for inspiration to buy or create your wooden side table, you’ve come to the right place. As a woodworker, my first project

My Top 10 Slimline Pen Designs – Wood, Acrylic & Resin

I’ve made many slimline pens in the past two years, but I’ve always kept the best for my own “private collection”. Some of these can

Scraper Burnisher DIY Kit Review

This is a short review of an unhandled scraper burnisher that I purchased from Taytools. You can buy a good Crown burnisher for about $23,

Wooden Cup Coasters – DIY From Pen Blanks

If you’re thinking about getting a wooden cup coaster for yourself or a friend, here’s how you can DIY one in under an hour. This

Cheap Spokeshave Review (Aliexpress Stanley Clone)

If you’re looking to purchase a cheap spokeshave from websites like AliExpress, you might want to read this short review to learn what I discovered

Best Woodworking Bench for 2024 – Budget and Premium Workbenches

What are the best woodworking benches you can buy today? Find out now, from our carefully-selected list of workbenches that scored the highest on Amazon!

Evapo-Rust “Rust-Block” Review – Does It Really Stop Rust?

I came across the Evapo-Rust Rust-Block solution while looking for ways to make sure my plane iron and sole stay clean and rust-free for as